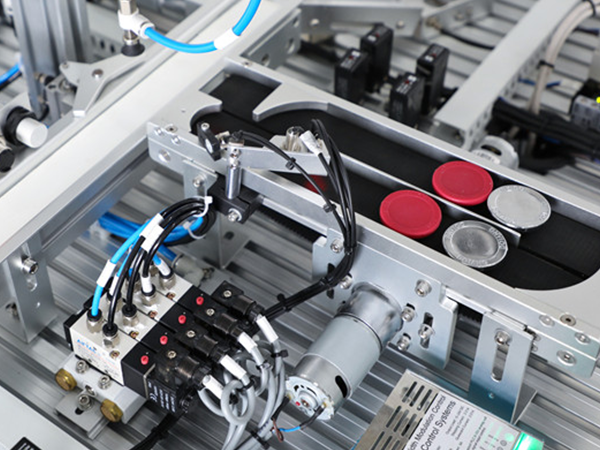

Anyang sensor cables are engineered to meet the high-precision signal transmission demands of industrial automation equipment. They are widely used in industrial control systems, automated production lines, measuring instruments, and other applications requiring precise signal transmission.

These cables excel in anti-interference capability, stable signal transmission, environmental and corrosion resistance, and are available in various specifications to adapt to complex industrial environments. Featuring high-quality conductors and premium insulation materials, Anyang sensor cables ensure long-term stability in harsh conditions, making them an ideal choice for industrial control and automation applications.

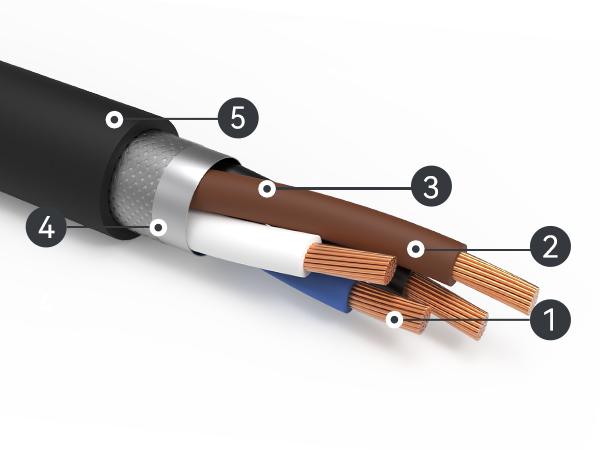

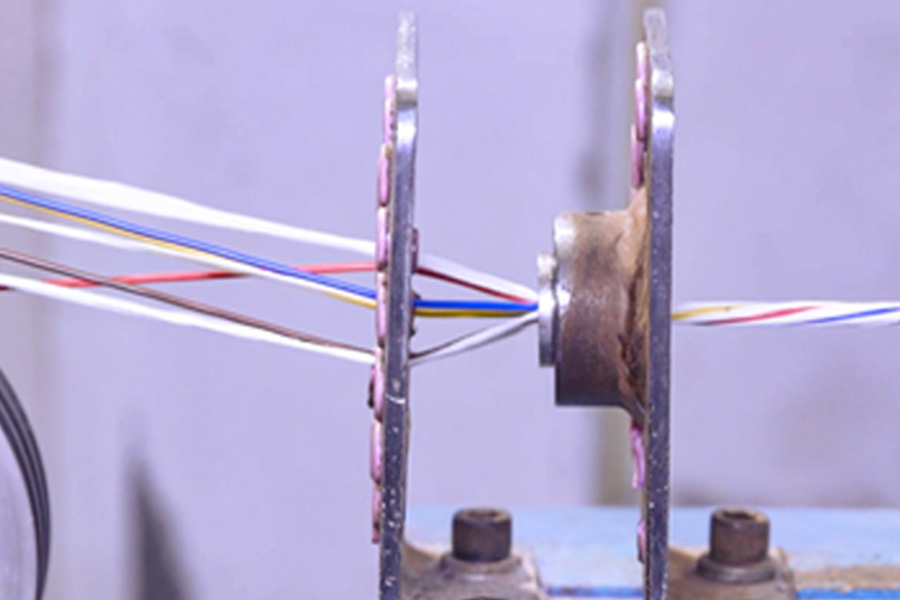

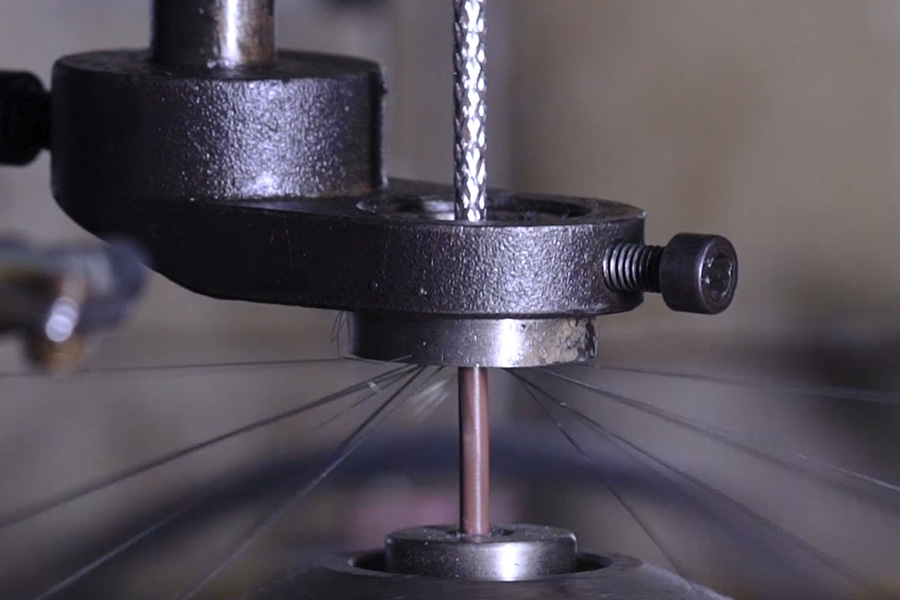

Motion-optimized stranding, wire diameter, pitch and orientation combination to optimize the bending resistance of motion cables.

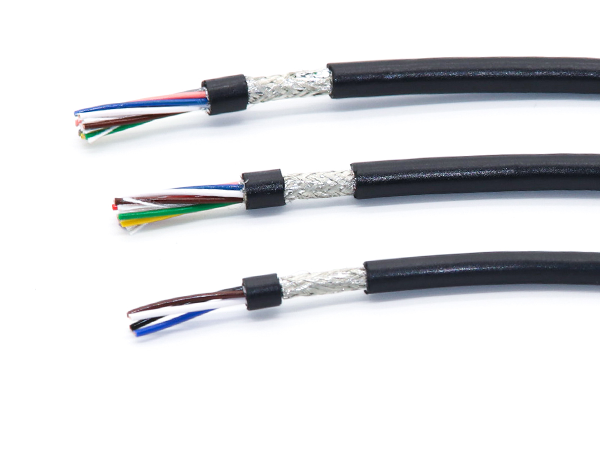

The full shield with optimized braiding angle (line coverage of about 70%, optical coverage of about 90%) adopts optimized pitch and direction twisting, and still maintains good shielding performance after long-term bending back and forth.

Optimized pitch and pitch twisting, full shielding with optimized braiding angle, and high-pressure molded outer sheath always keep the structure stable.

Optimal wire diameter, pitch, and direction improve motion cable bend resistance.

Internal cable insulation must remain non-adhesive

Built with a strong, high-tensile core and short pitch length.

Fully shielded with an optimal braiding angle (70% line, 90% optical coverage).

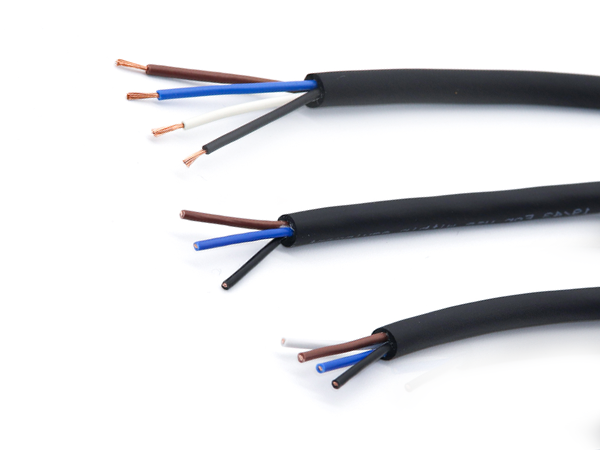

The outer sheath, available in PVC, PUR, or TPE, can be tailored for UV, low-temperature, or oil resistance ect.

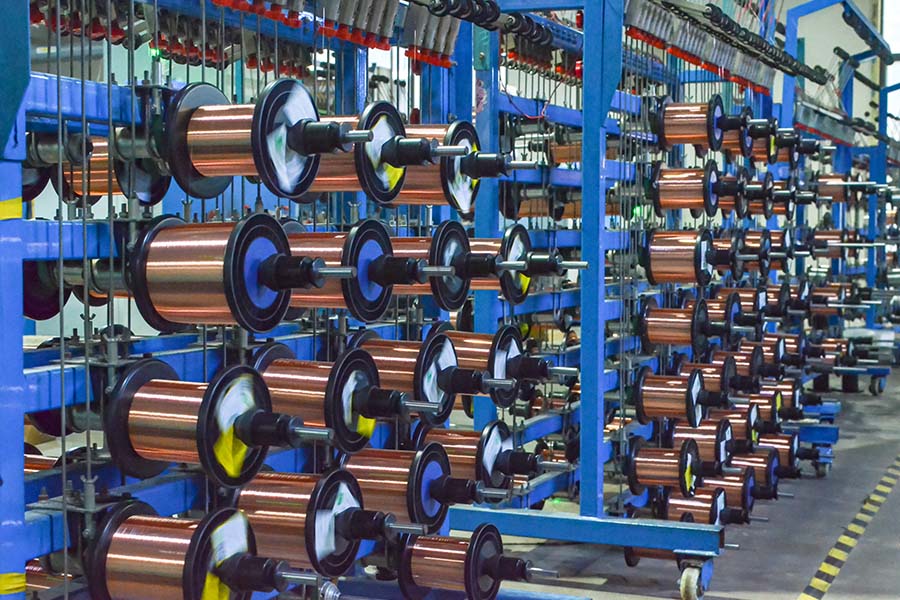

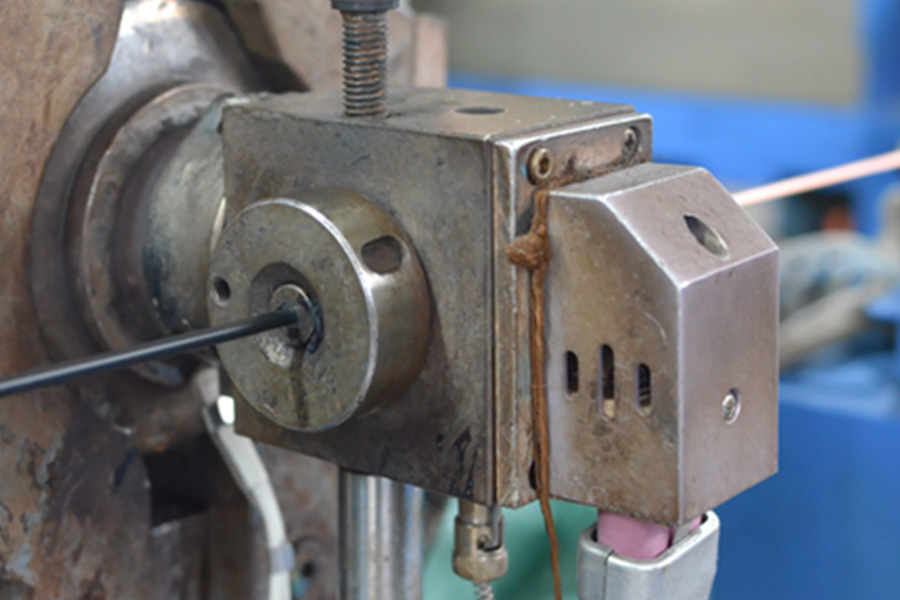

Using machines imported from Germany, 99.9% oxygen-free copper stranding is performed accurately to ensure the best performance of the cable.

The core wire size is uniform and not eccentric, and is extruded into shape.

Surrounding the tight center, the cable structure is stable, ensuring the cable movement performance.

High-density tinned copper braided shielding combined with appropriate angles achieves the best balance between anti-interference performance and motion performance.

Our TUV-standard labs and testing centers feature advanced equipment, conducting tests like swing, bending, drag chain, aging, low-temperature, torsion, electrical, salt spray, combustion, and tension tests. Rigorous quality inspections ensure each product meets standards, delivering reliable quality assurance.

The company follows ISO 9001 management, with products certified by UL, CE, CCC, RoHS, TUV, and VDE, and holds more than 35 national cable patents.

Our warehouse and ample standing inventory enable faster order delivery, reduced production costs, and effective solutions for urgent customer needs.