Selection of servo motor cables

Servo motors are an indispensable component in the fields of automation, industrial manufacturing, and CNC machines. So, how should we choose the connecting cables? Regardless of the brand of the cables, the usage methods will not vary much. For example, the cables from Panasonic, Mitsubishi, and Huacon are similar. Generally, servo cables include power lines, brake lines, and encoder lines. Servo motors can be classified into two types based on power: small-power servo motors and large-power motors. Motors with a power of less than 750W are considered small-power motors, while the opposite is usually large-power motors.

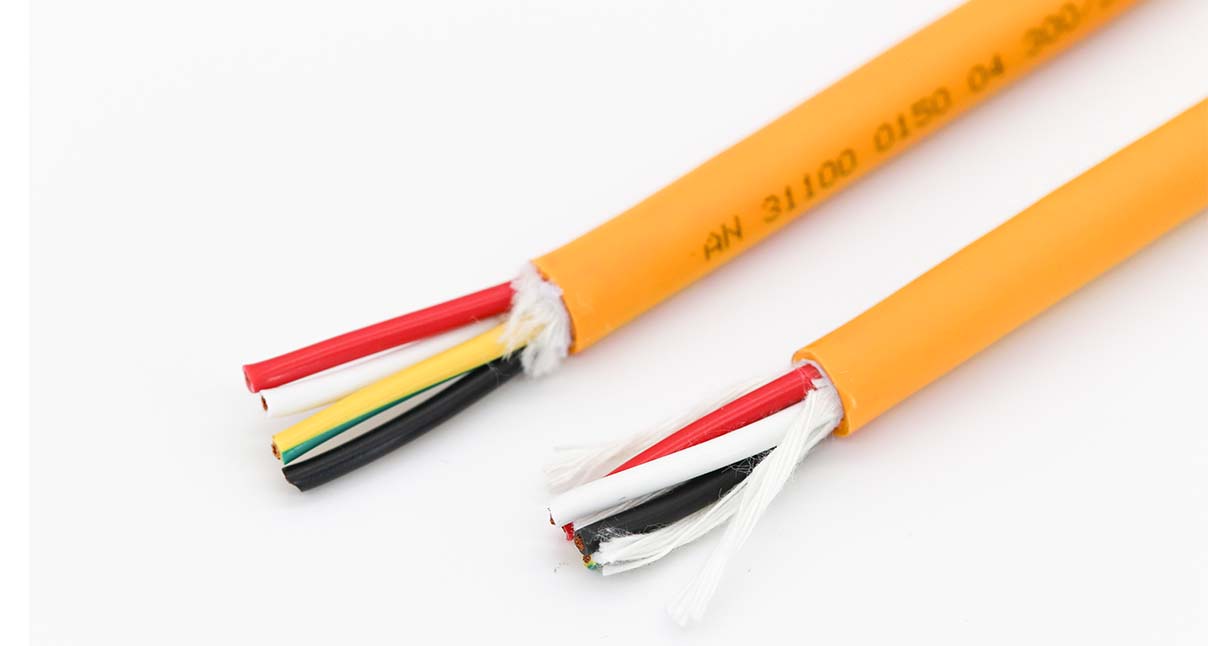

Power cord is also known as power line: The power cable is usually a 4-core cable, or it can be a 3-core cable (not grounded), consisting of U, V, W and PE. It serves as the power bridge connecting the motor and the driver.

Encoder wire: Responsible for transmitting signals to the motor. It consists of 2 pairs or 3 pairs of wires. The incremental option can be 4 pairs, or even 7 pairs.

Brake wire: Generally, it is a 2-core cable, responsible for controlling the operation of the motor. It is usually a 2-core cable.

Power cable selection: For small power motors, you can choose 4*0.5 or 4*0.75 specifications. For large power motors, choose 4*1.0 or 4*1.5 specifications. If it exceeds 2500W, it is recommended to choose 4*2.5 or higher. The specific selection should be based on the square number corresponding to the motor power.

Encoder wire selection: The main function of the encoder wire is to transmit signals, and the current it carries is relatively small. However, its anti-interference performance is particularly high. Therefore, the structure should choose twisted pair and shielded type to resist external interference. Incremental encoder wires can use 2 pairs of 0.2 square (24AWG) twisted pair shielded cables, and absolute value encoder wires can use 3 pairs of 0.2 square (24AWG) twisted pair shielded cables. If the connection length is too long, it is recommended to use a cable of a higher square size (22AWG).

Cable usage scenarios selection:

According to different working environments, choose 2 million times servo series cables, 8 million times servo series cables, 15 million times cable for conveyor belts, and 30 million times cable for conveyor belts. According to the usage environment, customize cables suitable for the corresponding environment, such as oil resistance, wear resistance, etc..

Power wire selection:

4*0.5 square ≤ 750W

4*0.75 square ≤ 750W

4*1.0 square 750W - 1500W

4*1.5 square 750W - 2000W

4*2.5 square 2000W - 3500W

Encoder wire selection:

2*2*0.2 square Incremental

2*2*0.3 square Incremental 20 meters or more

3*2*0.2 square Absolute

3*2*0.3 square Absolute 20 meters or more